KME TECU ®️

TECU ® Classic

In the beginning, the architecture grade material is bright red rolled copper. But what follows is an ever-changing spectacle of weather, light and the natural, lively language of the material: After installation on the building, TECU® Classic retains its typical bright red copper colouring for a period of time. Changes are very gradual and not entirely predictable – just like the weather, which, in turn, is solely responsible for copper’s continual changes. First, the surface turns matt. Gradually, the material develops an oxide layer to protect it against the effects of weathering. This process brings with it striking colour variations through an entire range of brown and brown-violet tones, offering varying nuances according to change of light and season. Ultimately, on the sloping surfaces, the colour process yields a robust green patina – as is typical for copper surfaces. This patina lends the cladding its distinctive character, at the same time providing long-lasting protection for decades to come

TECU ® Oxid

Time-tested TECU® Classic quality copper with a completely different look: With TECU® Oxid, the initial bright, freshly-installed copper, and the gradual change of colour to shades of brown is simply bypassed. Natural changes on the building start immediately with a dark oxide layer. The process continues as with classical copper: Nature changes the surface through the effects of sun, rain, snow and wind, giving it an exciting life of its own – always unique, typical copper. TECU® Oxid copper sheets and strips are pre-oxidised on both sides in a patented industrial process that is gentle on the material. The oxide layer is not artificial but results naturally from the copper itself.

TECU ® Patina

When the design demands the power and expressiveness of the patina green typical for copper, then it should be implemented just as required – without waiting for the gradual changes caused by natural weathering. The solution is TECU® Patina – on one side patinated copper for immediate use to satisfy the highest aesthetic demands in building design. TECU® Patina is always extremely varied, just as you would expect from a natural surface. The many different surface tones and shades eventually blend together, but only gradually. The unique developments occurring in TECU® Patina are exciting – just as modern architecture should be. The temporary yet robust transparent layer ensures long-lasting protection. Processing is virtually dust-free. Traces of processing remain practically invisible on the material surface, and even after folding and bending, the patina layer remains in good condition. After installation, the surface develops in the completely natural manner characteristic of copper. KME is now in a position to additionally offer four archetypal versions of natural patina, based on the proven industrial manufacturing procedure for the well-known TECU® Patina. The expansion of the TECU® Patina line of products therefore provides architects, installers and planners with additional design options, which will certainly also meet with great interest in the field of historic building preservation. TECU® Patina again proves to be extremely versatile, as is typical for natural surfaces. New diversity for a green facade.

TECU ® Premium

TECU® Premium is an innovative alloy of copper with a small proportion of high-grade tin for easy processing, for an extraordinary appearance from the very beginning and for intensive and rapid oxidation.

TECU® Premium from KME is new! We round off the range of TECU® products with a light bronze, by alloying our copper with a small proportion of tin. TECU® Premium has an extraordinary appearance! The material has a finely beaded pre-structure and a matte finish. Subtle reflections ensure an elegant appearance when light strikes it. Its particular surface structure enables a special oxidation pattern: it oxidises faster and more intensively and evenly, with a more matte finish than the well known plain rolled TECU® products. TECU® Premium can be excellently processed with modern cladding techniques as well as with traditional metalworking craftsmanship. It is slightly harder than ‘normal’ copper and can be better soldered thanks to its tin content. TECU® Premium is available in sheets or coils in various thicknesses. TECU® Premium belongs to the “TECU® Ecological Copper Alloys” and is predestined for certified green buildings. All components of the alloy originate 100% from recycled material.

TECU ® Bronze

Bronze – an alloy of copper and tin and a synonym for metallic works of art. While artists have long made use of bronze, architects are now also able to make optimum use of the material – for more refinement in façade design.

The original warm reddish-brown surface of TECU® Bronze develops in a distinctive manner through weathering. A brown-red surface oxidation with a brown-grey undertone is typical for this alloy; the material then gradually changes to dark brown anthracite throughout. The subsequent patina coating forms much more slowly than with pure copper.

TECU ® Gold

Gold is more than overpowering gloss: TECU® Gold, the new copper and aluminium alloy for façade cladding, will soon after installation begin to develop a very elegant matt brown-golden appearance reminding of gold in a very specific way. Façade solutions in TECU® Gold give buildings a discreet value image. Depending on the incidence of light on façade surfaces, a fascinating, unequalled play of colours can be witnessed.

TECU ® Iron

TECU® Iron complements the TECU® product portfolio by adding an interesting and extraordinary option, which is already attracting a considerable degree of attention amongst architects and planners: an intensive reddish-brown copper surface finish, bringing weathered steel to mind, but also with all the positive features associated with copper, such as excellent formability, unrivalled durability and ease of processing. Light and shade, bright and dark, dry and wet – all generate different optical nuances that make TECU® Iron a popular material for metal roofs and facades. TECU® Iron also repeatedly proves to be versatile and extremely lively, a feature typical for natural surface finishes; the nuances and shades of the surface blend gradually as time goes on. After installation on the object, the surface continues to develop. The individual development is extremely fascinating – just as modern architecture should be. Another decisive advantage: TECU® Iron is made exclusively and to 100% from recycled copper! This significant added value of many TECU® products can be a decisive argument in favour of use in buildings with LEED, BREEAM or DGNB certificates, which are increasingly in demand, particularly for public buildings. TECU® Ecological Copper complies in all properties with materials made of new metals and surpasses all requirements of the European standard EN 1172.

TECU ® Design

Amorphous structures, wave shapes, organic three-dimensional patterns, spherical impressions in copper: TECU® surfaces are now complemented by a third dimension. For building applications this means livelier, more individual facades with a very expressive presence. The natural copper surfaces now seem to take on a different appearance at different times of the day and with every change in light and shadow. The long-term change in appearance also seems to occur in a different manner from what we are used to: since the natural oxidation process on copper depends on the angle of the surface, the colour changes on three-dimensional surfaces differ considerably.

Amorphous structures, wave shapes, organic three-dimensional patterns, spherical impressions in copper: TECU® surfaces are now complemented by a third dimension. For building applications this means livelier, more individual facades with a very expressive presence. The natural copper surfaces now seem to take on a different appearance at different times of the day and with every change in light and shadow. The long-term change in appearance also seems to occur in a different manner from what we are used to: since the natural oxidation process on copper depends on the angle of the surface, the colour changes on three-dimensional surfaces differ considerably.

The material is first perforated and then stretched to create a copper rib mesh – a metal curtain with functional aesthetic qualities. The many different textile-like structures of the TECU®_mesh surfaces provide openness and create a solid barrier, offering both transparency and mechanical protection. TECU®_mesh surfaces in rib mesh design – for individual and characteristic impressions of light and space.

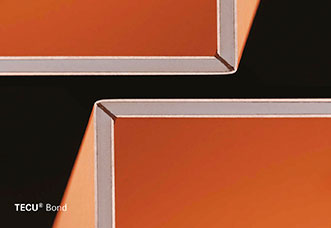

TECU ® Bond

Cladding large façades and interior areas quickly and economically with TECU® quality copper – without compromising on the outward appearance. Never before have projects been so easy to implement as with TECU® Bond. The new composite material offers all the aesthetic properties of the TECU® surfaces but can be cut to size and installed on large areas much more quickly and easily. TECU® Bond is extremely even and warp resistant, has an optimised weight, low thermal expansion and high mechanical resistance to wind loads, impact, shock and pressure. The material construction is amazingly simple and efficient: under high pressure, face sheets of TECU® copper or copper alloys are applied onto both sides to a FR-core made of plastic and mineral components. This creates an extremely robust composite material.

TECU® Bond is prepared and cut to size in the workshop; the sheets are then installed on the building site in no time at all. And to prevent damage to the materials, as can happen in a rush, a protective film is applied to the visible surface in the factory. The film is removed after the sheets have been installed. Thus, TECU® Bond offers elegant solutions at a reasonable cost for many projects such as ventilated curtain walls, fascia, parapet and soffit cladding, roofing and interior work and many more.